The importance of enameled wire in the aerospace fieldThe aerospace field has extremely strict requirements for electrical systems, and each component must work stably under extreme environmental conditions. In this challenging field, enameled wire plays a key role in electrical connections with its unique properties. Why is enameled wire so important in aerospace wire?

First, aerospace vehicles often face extreme environmental conditions such as temperature, humidity, and radiation. Enameled wire is covered with insulating enamel, which allows it to maintain stable electrical performance in high temperature, low temperature and humid environments. This insulation layer can effectively isolate the wire from the external environment and prevent the wire from being corroded and damaged by moisture, chemicals, etc.

Secondly, aerospace vehicles often face high-frequency vibrations and shocks because they experience varying degrees of mechanical stress during launch, landing, and flight. The flexibility and vibration resistance of enameled wire make it an ideal choice in electrical systems to maintain connection reliability in a variety of extreme situations.

Finally, the aerospace industry has very strict requirements on weight, because every additional gram of weight affects the carrying capacity of the entire spacecraft. Due to its lightweight design, enameled wire can not only reduce the overall weight of the spacecraft, but also help improve fuel efficiency, which is in line with the pursuit of lightweight and high efficiency in the aerospace field.

Criteria for selecting enameled wires in aerospace wires

Criteria for selecting enameled wires in aerospace wiresSelecting the appropriate enameled wire in aerospace electrical systems is a rigorous process that requires meeting a range of standards and requirements. The following are the main criteria for selecting enameled wire in aerospace wire:

High temperature resistance: Since aerospace vehicles will face extreme high temperatures outside the atmosphere, enameled wire must be able to work stably for a long time in a high temperature environment. Therefore, high temperature resistance is one of the important criteria for selecting enameled wire.

Radiation resistance: Aerospace vehicles will be subject to strong radiation in space, which places extremely high requirements on electrical systems. The insulation layer of the enameled wire must be able to effectively block radiation and protect the electrical signals within the wire from interference.

Anti-vibration and impact resistance: Spacecraft will be subject to severe vibration and impact during launch and flight, so the enameled wire must have sufficient anti-vibration and impact resistance to maintain the stability of the electrical connection.

Lightweight design: Due to the extreme sensitivity to weight in the aerospace industry, enameled wire must adopt a lightweight design to reduce the weight of the entire electrical system.

Chemical corrosion resistance: Enameled wire must be able to resist corrosion from various chemical substances to ensure stable electrical performance under harsh environmental conditions.

Conductive properties: Although enameled wire is mainly used for insulation and protection, its conductive properties are still a key factor in selection. The electrical conductivity of enameled wire must be good enough to ensure the transmission quality of electrical signals.

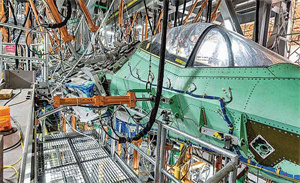

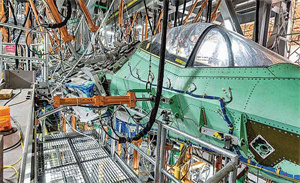

Application of enameled wire in aerospace wireEnameled wire is widely used in the aerospace field, covering many aspects of electrical systems. The following are the main applications of enameled wires in aerospace wires:

Flight control system: The flight control system is one of the most critical systems in aerospace vehicles, involving real-time monitoring and control of flight attitude, heading, altitude and other parameters. Enameled wires are often used to connect various sensors, actuators and control units in flight control systems to ensure that aircraft can perform various tasks stably and accurately.

Communication system: The spacecraft needs to communicate with the ground control center, other spacecraft or satellites, etc. Enameled wire plays a key role in aerospace communication systems, used to connect communication equipment and ensure reliable data transmission.

Power supply system: Enameled wire is also commonly used in the power supply system of aerospace vehicles to connect solar panels, battery packs and power management units. Its lightweight design helps reduce the overall weight of the power system and improve energy efficiency.

Navigation system: Enameled wire plays an irreplaceable role in the navigation system of aerospace vehicles. Connect the inertial navigation unit, GPS receiver, computer and other components to ensure that the navigation system accurately monitors the position and direction of the aircraft.

Scientific experimental instruments: In some aerospace missions, carrying scientific experimental instruments is indispensable. Enameled wire provides scientists with reliable electrical connections in the process of connecting these experimental instruments.

SummarizeThe application of

enameled wire in the aerospace field not only reflects its unique advantages in electrical connections, but also demonstrates its reliability and stability in extreme environments. As a lightweight, high-temperature-resistant, and vibration-resistant electrical connection material, enameled wire provides reliable electrical connections for various systems of aerospace vehicles, ensuring the normal operation of aircraft in extreme environments.

In the future, with the continuous development of aerospace technology, enameled wire is expected to be further optimized in design and performance to meet more complex and demanding tasks. Its continuous improvements in lightweight design, stability in high-temperature environments, and radiation resistance will provide strong support for the innovation and progress of aerospace electrical systems. As an important part of the aerospace field, enameled wire will continue to play an irreplaceable role in human exploration of space and in promoting scientific research and technological development.