At the 2024 NET ZERO Photovoltaic Industry Conference hosted by SMM, Zhang Pik, senior researcher of battery research and development at JinkoSolar Co., Ltd., introduced the research progress of crystalline silicon solar cell reliability.

Battery ReliabilityThe quality of photovoltaic modules determines the quality of photovoltaic power stations, and is also the decisive condition for whether photovoltaic power stations can operate effectively and stably for decades.

As the core material of photovoltaic modules, photovoltaic cells have excellent anti-attenuation ability, electrochemical stability, low hot spot effect, oxygen ring defects, mechanical load, and other quality assurance needs to consider the risks of the product throughout its life cycle and take preventive measures in the design stage;

Through a variety of standard test methods to improve the evaluation of product aging failure.

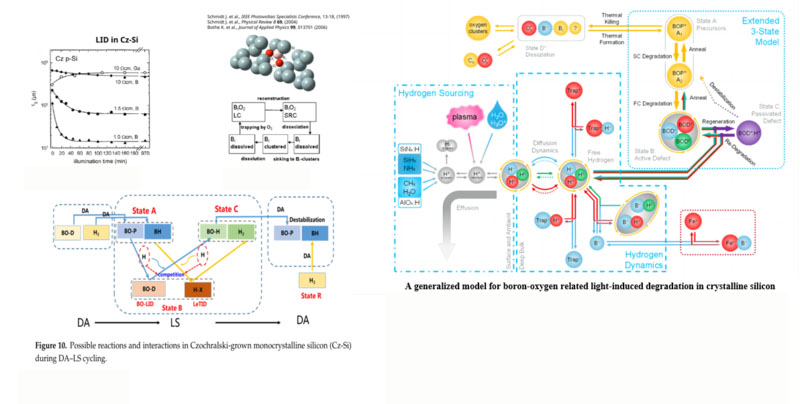

In addition, he also introduced 4 existing battery-side IEC standards involving attenuation, measurement and EL classification, and conducted experimental tests on "LID attenuation: mainly related to boron-oxygen pairs (iron-boron, etc.)".

IEC 63202-1 contains requirements for measuring the initial light-induced degradation (LID) of crystalline silicon photovoltaic cells. The risk of LID degradation of photovoltaic cells at moderate temperatures and initial durations is evaluated within the termination standard of 20 kWh·m-2.

Test Conditions:Temperature controlled within the range of (60±2)℃, irradiance of (1000±50)W·m2, relative humidity: ≤50%;

LeTID attenuation mechanism: not only bulk material attenuation, but also passivation attenuation

Studies have shown that dark annealing leads to the diffusion of hydrogen atoms, which are speculated to not only play a role in passivating impurities and defects, but also induce the formation of partial composite sensitive centers

IEC TS 63202-4:2022 describes the specific procedures for measuring the degradation (LeTID) of crystalline silicon photovoltaic cells caused by light and high temperature under simulated sunlight conditions

The attenuation rate, maximum attenuation rate and possible regeneration are determined by comparing the relationship between the maximum power Pmax of the ICE under standard test conditions (STC) during light radiation and the initial Pmax. The Pmax degradation curve under cumulative irradiation is proposed, which helps battery manufacturers determine whether the battery is prone to LeTID before assembling it into a component.

Wet heat DH test: used to evaluate the ability of the cell metallization paste to resist wet heat degradation

Jinko has completed and released the group standard in 2022, and the industry also uses acetic acid solution for evaluation

Potential Induced Degradation (PID)Sodium ion bias conditions are enriched on the surface of the photovoltaic cell, causing attenuation. If the sodium ions enter the battery matrix, the attenuation usually cannot be fully recovered.

Improving the density of the film layer and reducing the defects of the film layer are conducive to recovery after attenuation;

Battery EL black ring: The oxygen content of the silicon wafer is too high, and a radially distributed annular oxygen precipitation is generated during the high temperature process, which is displayed under EL/PL imaging technology

According to the characteristics of the black ring, it is divided into the following four categories: ringless battery, incomplete black ring, complete black ring, wide and deep black ring.

Battery EL black ring: The battery EL black ring is related to oxygen precipitation through the cause, which can be partially alleviated after the annealing process.

Enameled wire is mainly used to connect solar cell modules and the conductors between battery modules and other components to provide electrical connection and insulation protection.

From https://news.smm.cn/news/102955716

Welcome to see LP enameled wires, and LP can give you the best service.